Spot Facing

TODA SEIKI CO., LTD.

Back Spot Facing ・ Back Chamfering

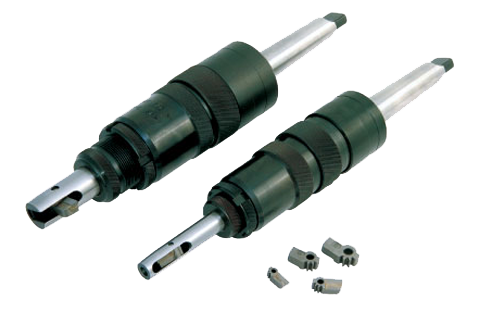

SPOT FACING is the innovative tool for back spot facing and back chamfering with easy handling, eliminating conventional complication of these operations.

Ideal for flange workpiece with dia12-45mm hole. It can be used in your milling machine or machining center, improving your machining efficiency.

Features

- Convenient for back spot facing and back chamfering with easy operation.

- Using on machining center or milling machine.

- Suitable for machining of flange parts with hole diameter 12mm (min) to 45mm (max).

- Back chamfering is also possible, only by manipulating adjusting screw to change angle.

- Thickness dimension after back spot facing will be maintained precisely.

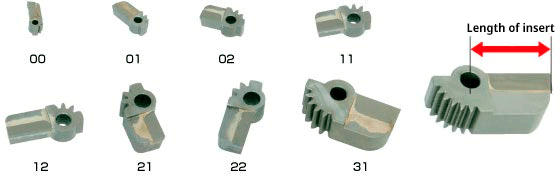

Insert for Back Spot Facing

Lost-wax casting for high rigidity

8 types of the inserts, to adjust for bolt hole diameter or c’bore diameter (from dia12mm-45mm)

Adjustable for any sizes of back counter bore diameter

| Code | Insert Number | Length of insert (mm) |

|---|---|---|

| SF-0 | 00 | (1/2 of c’bore dia) – 2 |

| 01 | (1/2 of c’bore dia) – 2.5 | |

| 02 | (1/2 of c’bore dia) – 3 | |

| SF-1 | 11 | (1/2 of c’bore dia) – 3 |

| 12 | ||

| SF-2 | 21 | (1/2 of c’bore dia) – 5 |

| 22 | ||

| SF-3 | 31 | (1/2 of c’bore dia) – 7.5 |

Spot facing is suitable for this kind of processing

Back chamfering, where is difficult to access,

can be performed in one go.

By adjusting the angle adjusting ring, back c’bore machining can be performed in one go.

Typical workpiece :

Valve flange, pump, engine parts, automobile parts, cylinder, hydraulic equipment, etc…